|

|

| Sprayable

Nanostructured Alumina / Titania S2613S Nanox™ Powder |

|

|

Thermal

Spray Grade Spray Dried

|

Alumina/Titania is a ceramic composite material

used as a wear resistant coating for machine components.

Nanox™ S2613S feedstock powder is agglomerated nanoparticles

with high flowability and an average diameter of 30 µm.

|

|

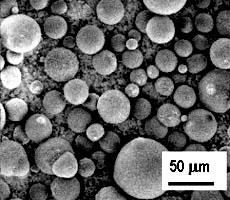

Morphology

SEM micrograph typical of Nanox™ S2613S feedstock powder showing

spherical geometry with high flowability.

|

|

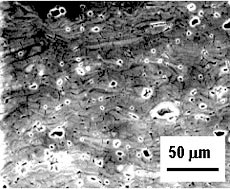

| Coating

Microstructure

Cross sectional

SEM view of a typical dense ceramic coating produced by a Metco

plasma gun using Nanox™ S2613S feedstock powder. Pores (dark

spots) occupy only 2 - 5 % volume.

|

|

| Year

2001 R&D 100 Award Winner

U.S.

Patent Nos. U.S.

Patent Nos.

6,025,034

6,162,530

6,277,448

6,277,774

6,287,714

|

| Properties

of NanoxTM S2613S Powder

| Al2O3

: TiO2 wt ratio |

87

: 13 |

| CeO2

content, wt % |

6

- 8 % |

| ZrO2

content, wt % |

8

- 10 % |

| powder

grain size (ave.) |

50

- 500 nm |

| agglomerated

powder size (ave.) |

30

µm |

| tap

density |

1.4

g/cm3 |

•

1 nanometer (nm) = 10 - 9 meter (m)

• Nanoscale Materials for the Global Infrastructure™

|

|

Suggested

Applications

Inframat® Nanox™ S2613S is an excellent thermal spray feedstock

for coating applications where resistance to wear, erosion, and corrosion

at elevated temperatures is required. The Thermal Spray Grade material

can be applied with DC Arc plasma guns. Full spray specifications

are available through Technical Applications Bulletin No. S2613S.01.A.

|

|

| |

|

|

|

| The

information and recommendations contained in this publication are based

upon data collected by Inframat® Corporation and believed to be correct.

However, no guarantee or warranty of any kind, expressed or implied, is

made with respect to the information contained herein, and Inframat® Corporation assumes no responsibility for the results of the use of these

products and processes described herein. No statements or recommendations

made herein are to be construed as inducements to infringe any relevant patent, now or hereafter

in existence.

|

|

|